Robot Building

Introduction

Most important part in building a simple robot is planning ahead. Every hour spend in thinking how to construct the robot, which materials and tools will be used, can save a lot of problems during the building phase. To reduce the risk of waisting time, experiments can be performed about the unknowns before the robot is built. For example, the way how the legs of the robot are attached to the servos without using hinges was first tested using wire, but wire proved to be too weak for holding the weight of the robot. Therefore, thick sheet metal is used in the robot which is stiff enough. The next sections describe how the robot was build as kind of a tutorial.

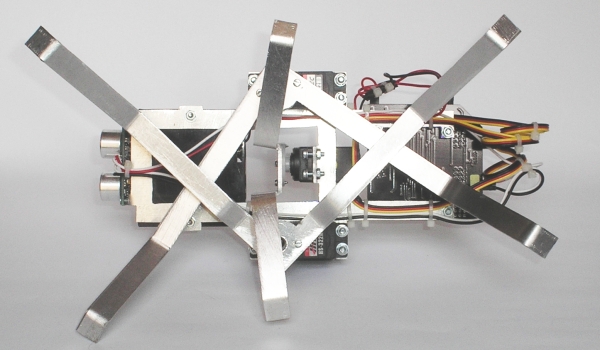

Figure 1: underside of the robot.

Robot Building Tools

The challenge of this robot is to build it without

professional tools. Of help here as well is aluminum, which is

an easy robot building material to work with. It's easy to

drill, cut or saw, and has the "high tech" look and

feel compared to other materials sometimes found in robots like

wood.

For drilling, an ordinary electric drill is used with HSS

(which stands for High Speed Steel) drill bits. To mark the

center location of the hole, a center punch is a very handy

tool to make a little dent in the aluminum. With this dent, the

drill is prevented from wandering off causing inaccurate

placement of the hole.

A coping saw is used to cut the sheet, and a set of pliers to

bend the sheet. For the electronic part of the robot, a

multimeter is a must-have, as well as a soldering iron. In this

robot design, no tools were used to make crimps, although to

make thing neat, it's recommended to make your own crimps.

Summing it up, following tools are used:

- Electric drill with HSS drill bits

- Center punch

- Hammer

- Coping saw

- Files

- Pliers

- Multimeter

- Soldering iron

How to Make a Simple Robot Body

To get an idea of the size of the robot, all robot parts

were laid out on a table the way they would be placed with

respect to each other. After some shifting, a good robot layout

was found, and the arrangement was sketched on aluminum sheet.

For this robot size, 1.4mm thick sheet fits well with the

relatively small design of this robot. Building larger robots,

requires thicker sheet. With this sketched layout, the contours

of the robot body were sketched on the sheet.

A coping saw was used to cut the metal. This went remarkably

well, it took approximately two hours to make the robot body as

shown in the pictures. A flat file was used to remove burrs and

sharp edges, and to straighten out the curved edges. A 3mm

drill was used for drilling the holes. A note about safety

here: be careful with drilling holes in sheet metal. The drill

can get jammed easy, especially with thin sheet and large

diameter drills. When holding the metal sheet stable, the sheet

can spin around rapidly when this happens, and acts like a

knife. Use a bench press, or something fixed to the table to

prevent the sheet from spinning counterclockwise. Never hold

sheet metal by hand when drilling.

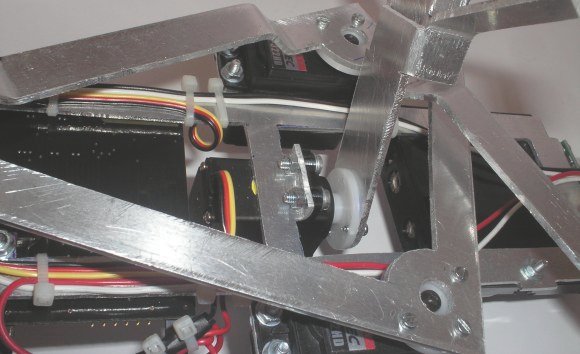

Figure 2: Detail of how the legs are attached to the

servos.

As can be seen in the picture above (Figure 2), the

middle robot servo is positioned with a 90 degree angle to the

robot frame. Therefore, part of the robot frame had to be bent

to mount the servo. A pair of pliers and some pieces of

aluminum sheet were used to experiment with bending the sheet.

Aluminum of this thickness results in a 3mm radius at a 90

degree angle. This means the holes need to be pretty close to

the bending radius in order to line up with the mounting holes

of the robot servo.

Easy Attachment of Legs to R/C Servos

On the Internet, the principle to attach brass wires with

paper clip wire to the servo wheels to act as legs can be

found. This method is simple, but unfortunately the brass wires

were not stiff enough to carry the weight of the robot.

It's probably a good way to construct robot legs for

smaller size robots, for instance when mini-servos and smaller

batteries are used. Even 1mm tick aluminum plate was not stiff

enough to act as legs, and finally a 2mm aluminum plate was

found strong enough to carry the robot's weight.

Using a center punch to mark the hole before drilling is

accurate enough for drilling the 2mm holes using an ordinary

portable drill. The challenge was

to drill holes of 8-9mm for for the servo wheels to fit in, see

again Figure 2.

Because the drill diameter is so large compared to the sheet

thickness, the drill jams into the sheet very easy.Last part of

the 9mm holes were filed away using a round bastard file.

Robot Assembly

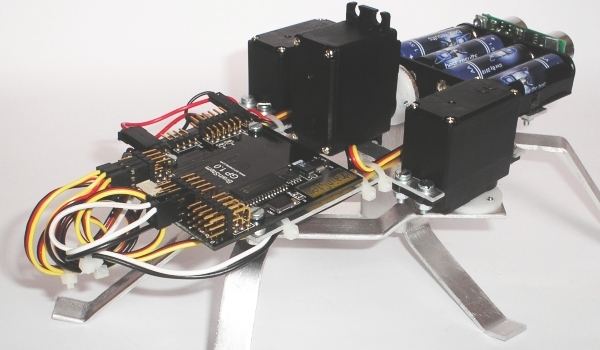

All parts were attached to the robot frame, and the

electrical wiring tied to the frame using tie wraps, see

Figure 3. Spare servo wires were soldered to the SRF04

ranger, and for making the servo power connection.

For both the SRF04 ranger, and the battery holder, M2.5 sunken

head bolts were used. The robot legs are attached using short

2mm parker screws (the Hitec servos come supplied with screws

used for attaching servo links, but they could not be used for

attaching metal sheet). After shopping some hardware stores, I

came to the conclusion M3 is the minimum size screws in these

kind of shops (in Holland that is), and they usually do not

sell thicker aluminum sheet than 1mm. For smaller sizes screws,

and for thicker sheets, one has to go to a R/C model shop, or

search the Internet and order on line.

Figure 3: Back side of the robot.

Improve Walking Performance and Ease of Use

Currently, the robot is being tested, and improved by

applying 2 switches to turn on the main power source, and to

disable movement. This is because the only way to switch on and

off the power is to put the batteries in the battery holder.

The servos are immediately energized once the power is up, and

can only be de-energized once user software is loaded, or when

the power is turned off again. The RS232 DB9 connector will be

fixed to the frame to be able to connect the robot easily to

the host computer.

Secondly, the SRF04 ranger detects flat objects well when they

are faced perpendicular to the ranger. When the robot is

walking towards a wall with an angle of approximately 45

degrees or more, the range finder will not detect the wall and

bump into it. Two options are being thought of: adding

microswitches to the robot's body or legs to detect a

collision, or to add a fourth servo to mount the ultrasonic

ranger onto to be able to move rotate the ranger sideways. The

latter is likely to be less complicated.

Robot Building History

1 January '05: The project started January 2005, by

browsing the internet. The first draft of this document was

created around this period as well.

3 August: Ordered parts at Acroname.

7 August: Published this web document.

16 August: Bought saw at toolshop.

20 August: Bought aluminum sheet and copper wire at hobby shop.

Started building the frame.

27 August: Searched for other material for the legs, and for

small size screws.

28 August: Bought aluminum sheet and small size screws at a R/C

hobby shop, finished building the robot.

29 August: Robot made it's first steps using TEA

programming language.

3 September: Made pictures of the robot, and published the

second version of this web document.

6 September: Lowered the robot 2cm. This is revision 2 of the

robot.

23 June '07: Finalized the new web-site.

This robot is featured in robot cafe and startpagina